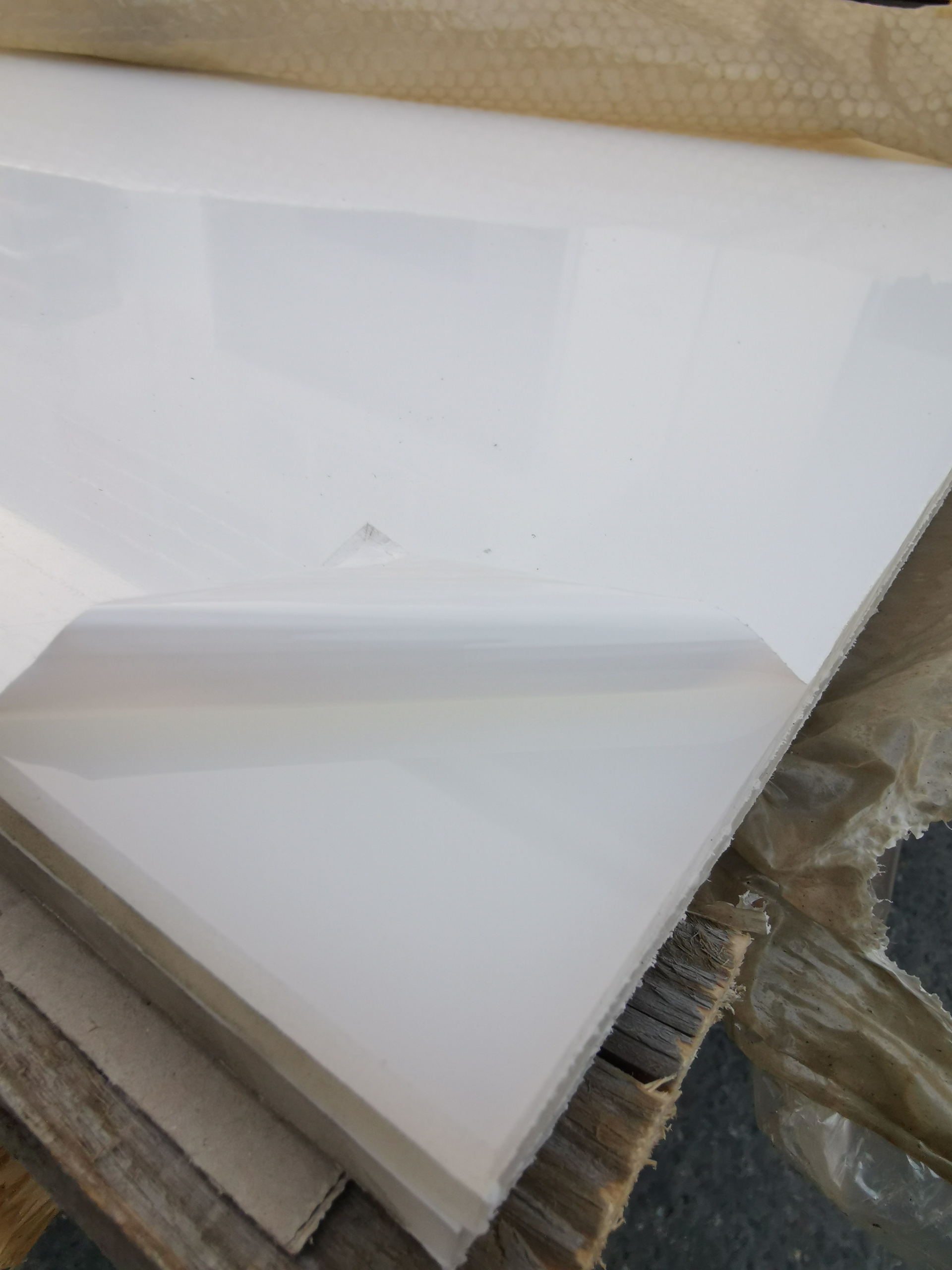

PVDF

Polyvinylidene Fluoride

PVDF (polyvinylidene fluoride) is a fluoropolymer that combines outstanding chemical resistance with outstanding strength and stability. Compared to traditional fluoropolymers such as PTFE, PVDF exhibits unparalleled resistance to even the harshest chemicals, even at temperatures up to 150 ° C, with up to three times more than typical strength and hardness values.

PVDF, polyvinylidene fluoride is a versatile fluoropolymer that is both strong and hard as reflected by its tensile properties and impact strengths. PVDF has excellent resistance to creep and fatigue. When load bearing is important, PVDF fluoropolymers are rigid and resistant to mechanical stress and crawling under load. It is stable against sunlight and other sources of ultraviolet radiation. An additional advantage over other fluoroplastics is that PVDF can be welded to tanks for acid and corrosive chemical processing in high temperature environments.

These properties, along with its inherent flame retardancy and ultra-high purity, have made it the material of choice for creating cleanroom environments of equipment components used in semiconductor manufacturing. It is also often used in components used for PVDF power transmission, as it offers excellent toughness and electrical properties that remain constant over a wide range of both frequencies and temperatures. PVDF sheets and rods are easily processed.

PVDF is often used in applications requiring purity, strength and resistance to solvents, acids, bases, heat and low smoke formation. A is a versatile fluoropolymer that is both strong and hard, reflected by its tensile properties and impact strengths. It is stable against sunlight and other sources of ultraviolet radiation. PVDF can be welded to tanks for acid and corrosive chemical processing in high temperature environments.

- 150 ° C Continuous Use Temperature

- Extremely Low Moisture Absorption

- Flame Resistant

- Very Resistant To Chemicals

- Superior Electrical Properties

- Mechanical strength and toughness

- High wear resistance

- High thermal stability

- High dielectric strength

- High purity

- Can be processed easily melted

- Resistance to most chemicals and solvents

- Resistance to ultraviolet and nuclear radiation

- Weather resistance

- Resistance to fungi

- Can be welded