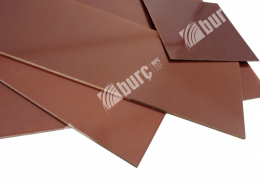

PHENOLIC (FIBER & BAKELITE) SHEETS AND RODS

A- Phenolic paper (Fiber) sheet and Rod

This laminated product is formed by heat pressing after the electrical industry alkali glass paper is dipped into phenolic resin. It has high mechanical and dielectric performance, and can be applied as insulation structural components for electromechanical, electrical equipment, as well as under humid ambient conditions and transformer oil.

B- Phenolic cotton fabric (Bakelite) sheet and Rod

Phenolic cotton cloth is made of bleached cotton and phenolic resin, additives, thermal curing and insulation layers. (Other Name: Bakelite Insulation Board, Bakelite Insulation Board, Bakelite Rod, Phenolic Cotton Cloth Laminated Sheet, Bakelite Cotton Rod).

It is made of insulation paper impregnated with phenolic resin and hot pressed, also called Bakelite or sometimes phenolic.

Bakelite is suitable for use in transformer oil, machinery, Motors and electrical devices where insulation parts and parts with high mechanical properties are required.

Bakelite sheet is a hard, dense material made by applying heat and pressure to layers of paper or glass cloth impregnated with phenolic resin. These laminating layers are usually cellulose paper, cotton fabrics, synthetic yarn fabrics, glass fabrics or nonwoven fabrics. When heat and pressure are applied to the layers, a chemical reaction (polymerization) transforms the layers into high-pressure heat-curing industrial laminated plastic.

- High mechanical properties

- Oil resistance

- Specific dielectric properties

- Temperature resistance: 120 ℃

- Heating Resistance: Class E

- Resistant to various chemical solvents and acid erosion